Principles and Applications of Air Assist

Many experienced users of laser engraving machines employ air assist, while newcomers often hesitate about its usage due to their lack of understanding about its specific functions and when to apply it for optimal results. Let's delve into the principles and applications of air assist.

I.Principles of Air Assist

First, let's understand the underlying principles of air assist.

①Cleaning Exhaust and Particles: During the laser engraving process, materials are vaporized, generating gases and vapors. These exhaust gases and vapors might interfere with the laser beam's focus, affecting engraving quality. Air assist involves jetting compressed air to swiftly blow away exhaust gases and vapors, maintaining the laser beam's clarity and stability, thereby ensuring engraving precision and quality.

②Oxidation and Combustion Control: In certain material engravings, such as organic materials, oxidation or combustion reactions can occur. Introducing compressed air forms a barrier of oxidants around the engraving area, reducing the likelihood of oxidation and combustion, thereby preserving engraving clarity and quality.

③Cooling and Temperature Reduction: Some materials can heat up under laser action, potentially causing deformation or damage. Air assist involves jetting cooled air to lower the engraving area's temperature, reducing material's heat impact and preventing damage.

④Particle Control: Certain materials generate tiny particles, known as laser dust, during laser engraving. These particles can adhere to the engraved surface, impacting the engraving quality. Introducing compressed air can blow away these particles, keeping the engraving area clean.

⑤Focus Maintenance: Air assist helps maintain the laser beam's focal point stability. The laser beam might experience defocusing when passing through optical elements like lenses and mirrors due to gas and particles. By clearing these disturbances, the laser beam's focusing performance is upheld.

II.Guidelines for Air Assist Airflow

①Gentle Cleaning: For mild engraving tasks, a smaller airflow might suffice to remove minor exhaust gases and particles produced. In such cases, the airflow setting can be kept low to avoid excessive cleaning and unnecessary material damage.

②Deep Engraving: Tasks requiring deep engraving, such as cutting, might necessitate stronger airflow to remove more exhaust gases, vapors, and particles. This helps maintain clear laser beam focus and prevents clutter in the engraving area.

③Material Characteristics: The type and characteristics of materials also influence the choice of airflow. Some materials might produce more exhaust gases during engraving, demanding a higher airflow for cleaning.

④Focus Maintenance: Situations requiring stable laser beam focus might call for moderate airflow to control gases and particles around optical components.

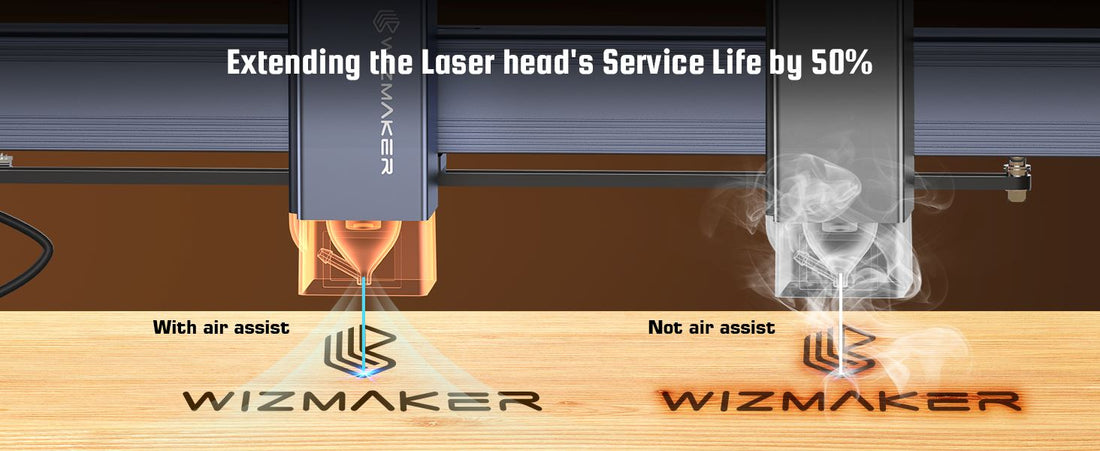

III. Effects of Using Air Assist vs. Not Using It (Engraving and Cutting)

①Engraving Effects:

a. Using Air Assist: Employing air assist effectively clears exhaust gases, smoke, and particles from the engraving area, maintaining clear and stable laser beam focus. This usually results in clearer and finer engraving effects, especially for intricate patterns and text.

b. Not Using Air Assist: Without air assist, the engraving area might accumulate exhaust gases and particles, leading to less clear engraving effects, particularly during prolonged engraving sessions.

②Cutting Effects:

a. Using Air Assist: During laser cutting, air assist clears produced exhaust gases, smoke, and vapors, maintaining laser beam focus and achieving higher quality cut lines. It also controls oxidation and combustion reactions, ensuring cutting quality.

b. Not Using Air Assist: Without air assist, exhaust gases and particles can accumulate in the cutting area, affecting cutting results, potentially resulting in rough or inconsistent cut lines.

IV. Applications of Air Assist in Laser Engraving and Cutting

①Laser Engraving Applications:

a. Marking and Engraving: In laser marking and engraving, air assist cleans the engraving area, preventing exhaust gases and particles from interfering with the laser beam, ensuring engraving clarity.

b. Art and Craft Production: Laser engraving finds wide application in art and craft production. Air assist helps maintain engraving details and quality.

c.Texture and Pattern Creation: Air assist prevents materials from overheating during engraving, keeping the engraving area clean, resulting in clear textures and patterns.

d. Surface Modification: Laser engraving is used for material surface modification, like enhancing adhesion or altering optical properties. Air assist controls engraving effects to achieve the desired modification.

②Laser Cutting Applications:

a. Metal Cutting: In laser metal cutting, air assist clears cutting area exhaust gases and smoke, maintaining laser beam focus for high-quality cut lines.

b. Wood and Plastic Cutting: Air assist prevents overheating in wood and plastic laser cutting, reducing the risk of burning and ensuring cutting quality.

c. Ceramic and Glass Cutting: Air assist clears dust from cutting areas, maintaining clear cut lines and preventing material fractures or breakage.

Ⅴ.Recommended Air Assist Solution

Based on the above information, you now have a better understanding of air assist. If you own a laser engraving machine, you might consider acquiring an air assist device. I recommend Wizmaker's Air Assist, which is compact yet powerful, featuring adjustable airflow ranging from 10-30L/min. If interested, you can directly purchase it through this link: https://www.wizmaker.com/products/wizmaker-air-assist-pump-for-most-laser-engraving-machines